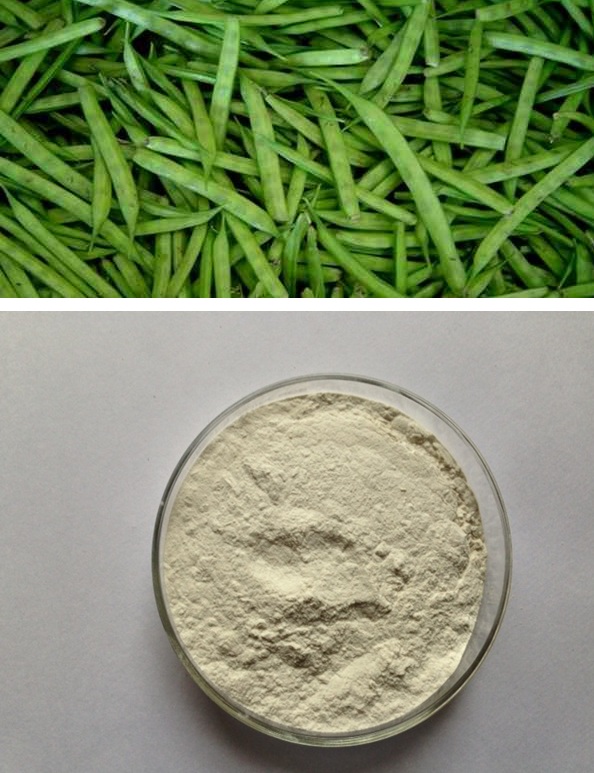

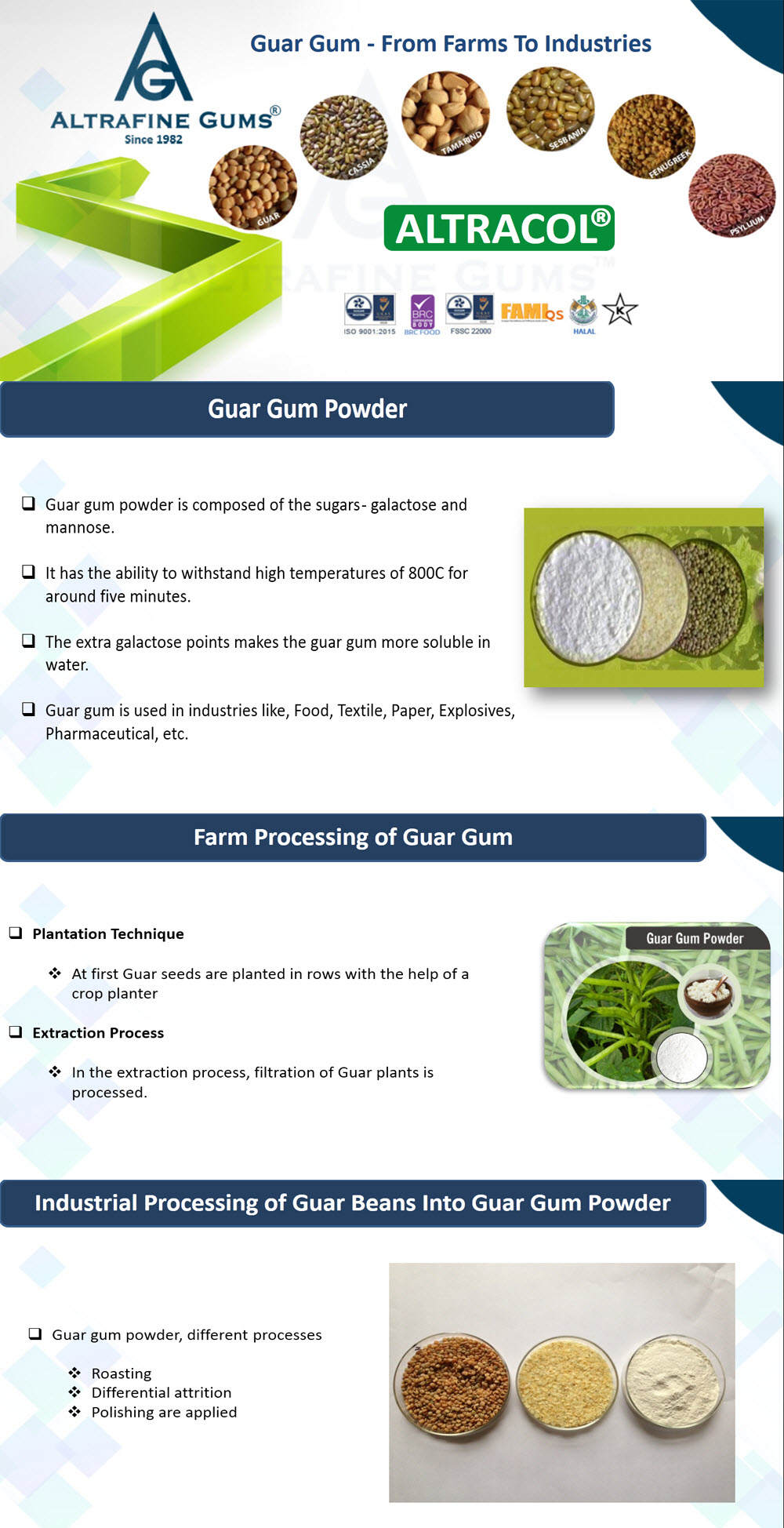

The production of guar gum begins with the separation of the seed husk and germ from the seed. The husk is charred with heat to improve extraction. The endosperm is then processed to yield powdered guar gum. Clarified guar gum has higher galactomannans content and is often used as a thickening agent.

Origin of Guar Gum

While the guar gum plant is native to India and Pakistan, it is now grown in southern hemisphere countries such as USA, Australia, and Africa. It is rich in fiber and is known to reduce harmful bacteria in the digestive system. This plant has many uses in human health. The husk is used in cooking while the germ is used in animal feeds.

Properties of Guar Seed

The seeds of the guar plant are spherical and brown. They are approximately the size of pea seeds. Once ripe, the seedlings can be harvested within a year. The guar seed is not soluble in water, so it is important to avoid direct grinding. The latter process causes more heat in the grinder, resulting in a less soluble product. Refined guar gum split is obtained by heating the plant. The plant is then processed into a powder.

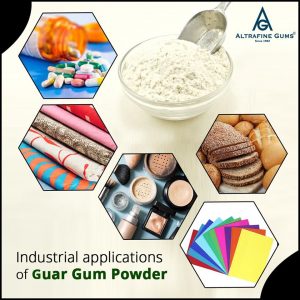

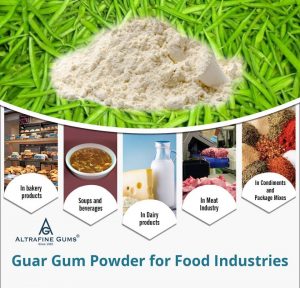

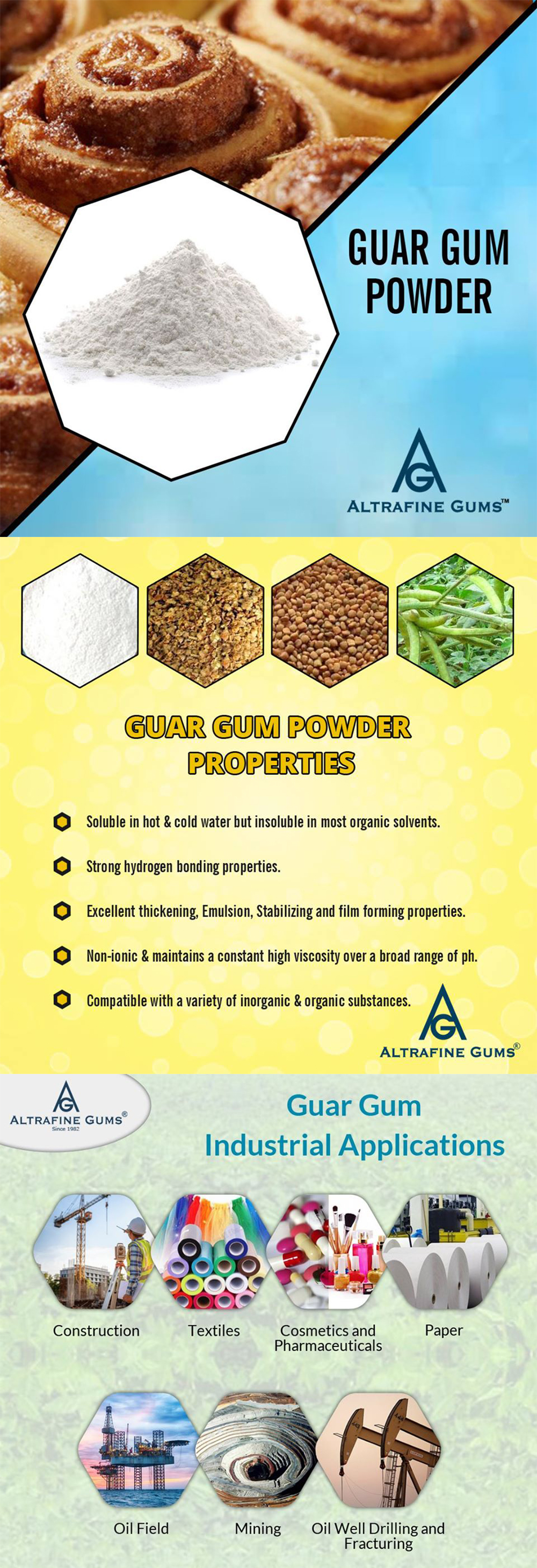

Features & Benefits of Guar Gum Powder

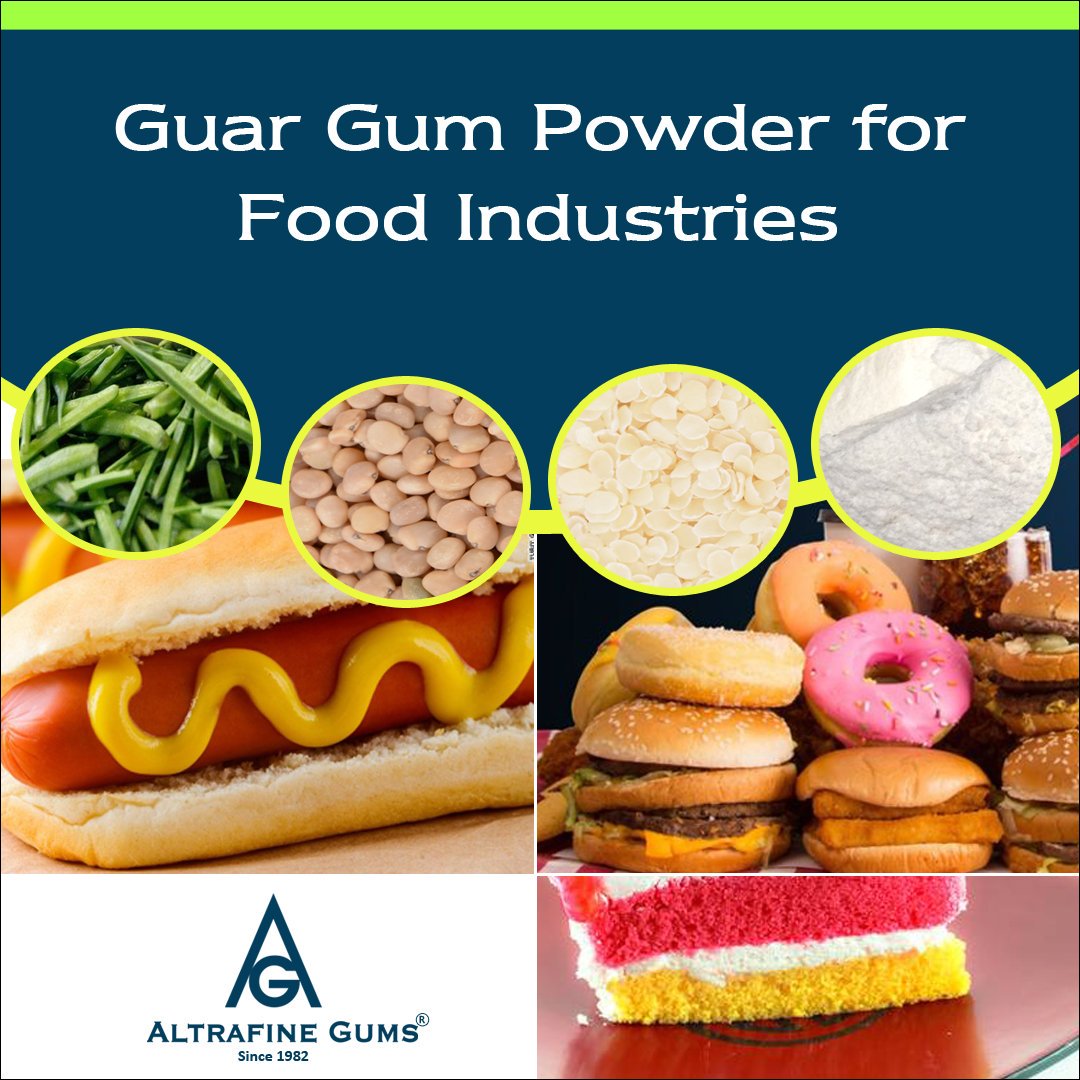

The guar gum is an edible carbohydrate polymer. It is obtained from the seeds of a leguminous plant. The Guar plant grows in semi-arid regions and has been used for centuries for both human and cattle feed. Today, guar gum is used in a variety of applications. The powder is also useful for making soap, toothpaste, and dental floss. It is a versatile substance and can be utilized in a variety of industries, including paints and aqueous slurry explosives.

The Bottom Line

The Guar plant is a member of the pea family. It is now grown in different parts of the world for its benefits and is known locally as a cluster bean. It was first introduced to the United States in 1903. The guar plant produces a gel from its seeds. This gum is extracted from the seeds and can be used in a variety of industries. It is an excellent source of protein for humans and animals. The guar gum plant is a leguminous plant that thrives in sunny areas. It is not a tropical plant. It grows best in warm, moist climates and needs a temperature of between 15 to 35 degrees Celsius.