Cassia powder is derived from the cassia tora plant. This is small annual herb that grows as a common weed in the Asian countries and found throughout India. The plant extract is most famous for use in traditional medicines to cure various disease as well as emerging industrial applications.

The cassia plant is a well known ayurvedic medicine plant acting as a laxative, expectorant, action on cardiac diseases liver tonic and many other conditions.

The cassia powder is derived from the grounded and purified endosperm of the seeds of cassia tora plant. Seeds are de husked and degermed through thermal and mechanical treatment followed by milling and screening of the endosperm , further purification is done using isopropanol and the end product is an off white fine cassia powder.

Phytochemistry in Cassia Powder

The medicinal value of the cassia powder extract is due to the Phytochemicals present in the seeds that produce definite physiological action to the human body. These bioactive compounds are alkaloids, carbohydrates, saponins, glycosides, proteins, tannins, phenols, anthraquinones, terpenoids and many others.

Ongoing scientific researches on the cassia powder suggest huge biological potential of the plant. Studies on the Phytochemicals and biological properties of the extracts show enough evidence for therapeutic value. The efficacy of the phytochemicals from the cassia is affected by the geographical locations where the plant occurs and extraction techniques.

Phytochemical Action

Antioxidant Activity: the methanolic extracts from the seeds shows strong antioxidant with the phenolic active ingredient being alaternin.

Antibacterial effects: these are brought about by the presence of phenolic glycoside and their aglycones and have been seen to have effects on E.Coli and other pseudomonas strains as well as some strains of staphylococcus.

Anthelmintic Activity: this has been shown due to the presence of flavanoids in the cassia gum extract. This action has been seen against Pheretima Posthuma and ascardia galli species.

Other Properties of Cassia Powder

The cassia gum powder is comprised of 75% polysaccharide with a ratio of mannose to galactose of about 5:1.these results are obtained from sugar analysis tests using the high performance liquid chromatography procedure. It has fewer galactose molecules next to the mannose chain. This has a significant effect on the synergy of food grade cassia powder with other anionic food gums like the carrageenan or Xanthan gum. This translates to lesser amounts of cassia powder being required for gelling effect, as to when the carrageenan is used alone.

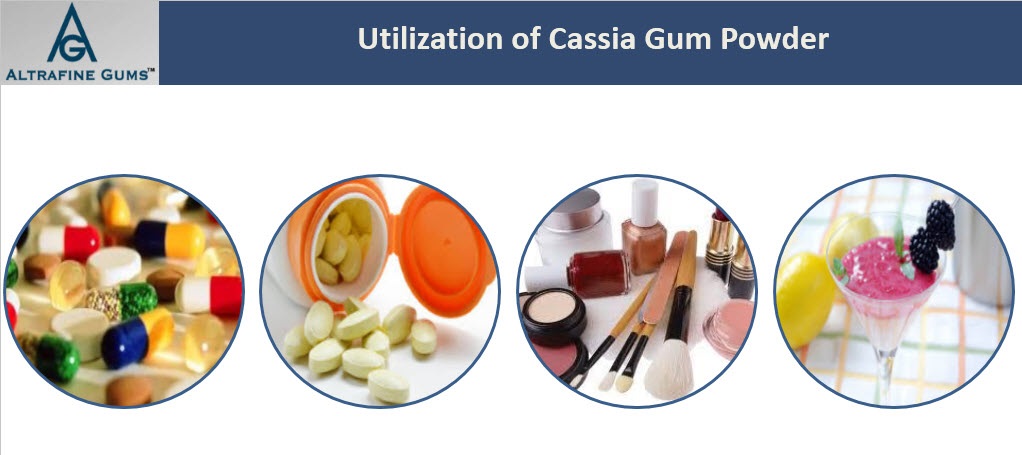

Some of the applications in foods include emulsifying, stabilizing, thickening, gelling and water retention properties. The foods processed using cassia powder includes cheeses, frozen dairy desserts, meat products and manufacturing of poultry products.

With the increasing shift towards use of natural based chemicals for food and therapeutic purposes, the cassia powder economic potential grows every day. The traditional medicinal value of the cassia gum as herbal remedy has stimulated further research on the phytochemicals of the plant and active ingredients of economic importance. More clinical and pharmacological studies with standardized extracts are needed to uncover the unexploited potential of the cassia gum plant in the food and pharmaceutical industry.