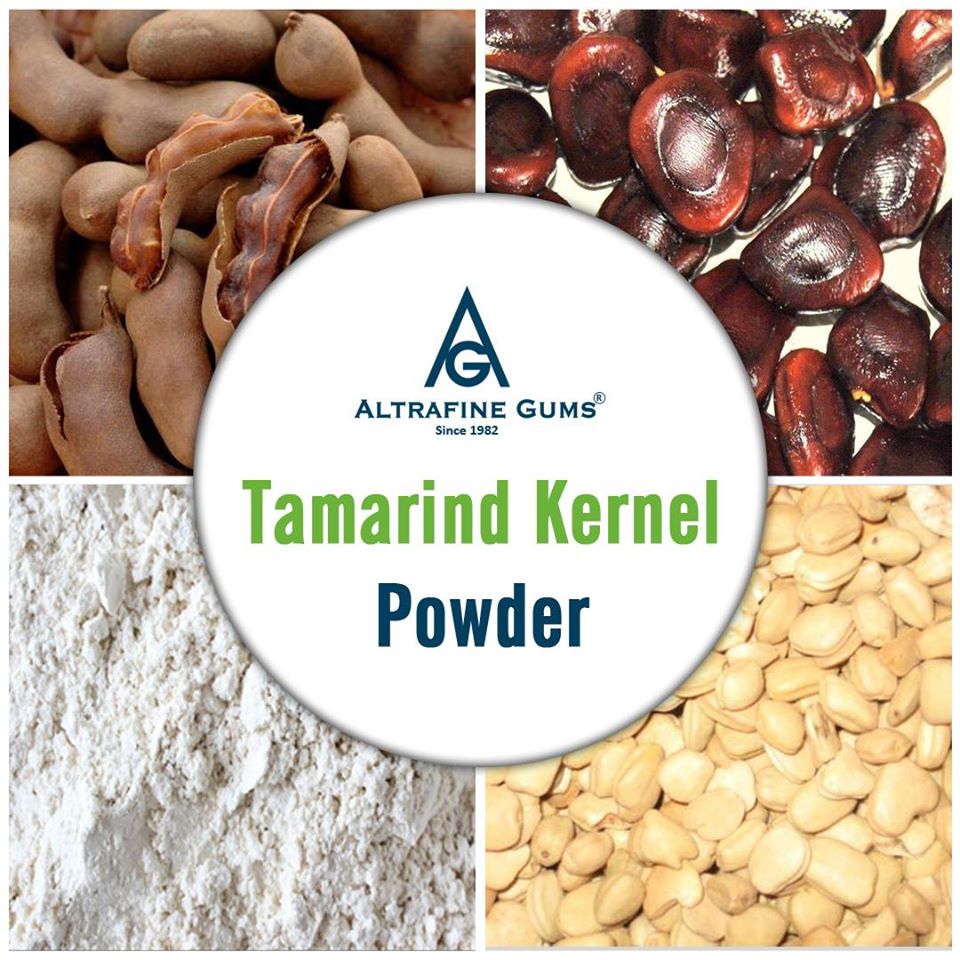

The Tamarind Kernel Powder is a natural polymer that has outstanding water absorption properties and high viscosity. It has various applications but amongst the most important ones is its use in the textile industry as a textile thickener and in its sizing. It is the most sought after and economical option due to its favouring characteristics.

How does it benefit the textile industry?

Textile Industry aims at producing designs in multiple colours on the material of the textile. This process involves a control in the speed of the dye and carefully prevents it from spreading beyond the boundary line of the design. Here is where the role of a thickener becomes important. A thickener like the Tamarind Kernel Powder acts as an important ingredient of the paste while imparting plasticity to the printing paste which helps in the dye not spreading across even under high-pressure conditions. The compounds of high molecular weight in it have the capability of turning into a vicious paste in water to hold all the dye particles in their desired place until the fixation of the dye is complete. Moreover, this is an economical alternative as it has the unique property of high viscosity at a low concentration which makes it a cost-effective additive in dispersal printing on polyester fabrics.

The Physical and Chemical Properties of the Tamarind Kernel Powder

The Tamarind Kernel Powder is creamy in colour (white to pale yellow). It is a polymer that is composed of the D- Mannose and D – Galactose units. It has the excellent property of high water absorption and the solutions derived from it can well retain the viscosity over a broad range of pH. When heated with water it forms a thick, viscous, and colloidal dispersion that produces strong, transparent, and elastic films on evaporating.

How is the Tamarind Kernel powder processed?

The tamarind seed powder, the tamarind gum, or the tamarind kernel powder is obtained from the endosperm part of the seed. It is made by decorticating the seed which is done by roasting and then de hulling to remove the seed coat. The seed is then ground well by the machinery as per the required mesh size in the form of a powder. The tamarind kernel powder is rich in a high molecular weight called the polysaccharide which makes it an excellent textile sizing agent.

The unique uses of the Tamarind kernel powder which makes it useful in textile sizing and other utilities–

- It can swell in water to form a mucilaginous solution after heating up which makes it an excellent thickener. The Powder also forms a gel quickly and is a quick replacement to the starch used previously due to its low cost.

- It is used in sizing jute and cotton yarns and has tremendous adhesion properties.

- The Tamarind gum-based materials are used in printing processes, as `fabric detergents and conditioning agents for fabrics.

- The Tamarind Kernel Powder is also used in the enzymatic stone washing of denim.

Conclusion

The Tamarind seed powder is a very budgeted, efficient, and good sizing material used widely in the textile industry and well as the jute sizing industry. Its demand continues to grow and the superior quality ones are exported extensively. State-of-the-art technology with innovative techniques is used by Tamarind kernel manufacturers to produce a rich and superior quality tamarind gum/ kernel powder which is demanded all across the globe.