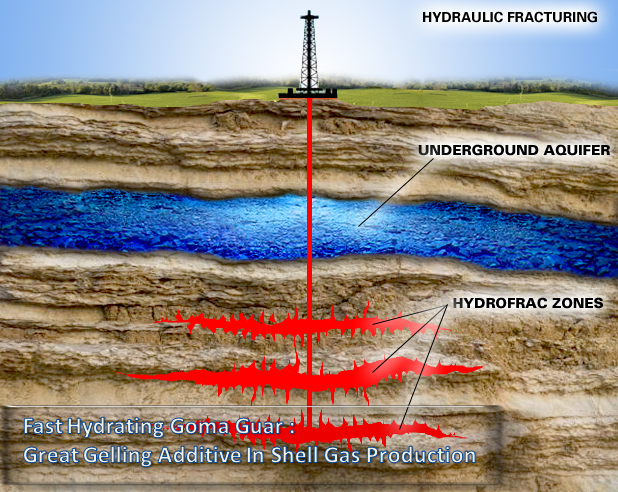

From the year 2005, there was a rapid shift in the usage patterns of the guar gum. Before then the major demand sectors for the guar was the food grade which consumed over 50% of the domestic production. There was also some demand for the fast hydration guar gum powder used in the paper and the cosmetic manufacturing.

This however changed when guar gum usage was directed to the oil and gas drilling operations. This industry now forms the bulk of the demand for the guar gum. Demand for the product has reached up to 70% of the total production. The rest is taken up by other industries such as textiles and food processing.

Prices

The prices of this product have a very high positive correlation with the shale gas exploration. Negative price movements have had major impacts on the overall well being of the industry.

Current Challenges

- Price uncertainties; these have caused mixed reactions among users which compel them to develop alternative products and processes to achieve the same goals.

- Supply challenges; the production of guar plant is much dependent on the monsoon rainfall. When these get delayed, forecasting the production levels becomes very difficult, thus creating instability in the market.

- Quality product; this is a very important element especially in the food grade guar gum powder. Slight contamination leads to serious consequences including product withdrawal, and export bans especially from Europe and the UK.

- Usage of proplant; the guar gum is used in industry for increasing the viscosity of the proplant. Market uncertainties have caused the users to consider using slick water that requires less guar usage. This will have serious effect on the future of this product.

- Earlier calls for reduction in oil and gas exploration have also been a major factor affecting the market of the guar gum.

- The emergence of other gelling and emulsifying agents such as the synthetic LFC – C4, developed in the UK, will cause a definite shift in the demand curve of the guar.

Strategies for Market Development

To counter the effects of these forces, strategies must continue to be developed that will help maintain the demand of the product.

- There is an urgent need to diversify the market to other major oil producers and other places where oil and gas exploration is emerging.

- Greater resources must be put into research and development to discover other uses for the product.

- There is also need for continued research on better processing technologies that will eliminate challenges associated with poor quality. These include production using high quality seeds as well, proper production practices, good extraction technology as well as packaging , branding and market promotion.