The demand for natural ingredients in the food industry has risen dramatically in recent years, with consumers and manufacturers alike prioritizing cleaner, more sustainable products. One such ingredient gaining significant traction is cassia gum powder. Derived from the Cassia tora plant, cassia gum is becoming increasingly popular in Finland, particularly in the pet food and frozen foods sectors. Known for its high gelling and thickening properties, cassia gum powder serves as a functional additive that helps enhance texture, consistency and stability in a range of food products.

In Finland, where the food industry is continually evolving to meet the needs of both domestic and international markets, cassia gum powder is playing a pivotal role. It is now used extensively in pet food formulations and frozen meals, offering an alternative to synthetic additives and stabilizers. This article explores the various roles of cassia gum powder in pet food and frozen foods sectors, the market dynamics surrounding its use and the production and supply considerations that impact its availability in the country.

Why Cassia Gum Powder is used in Finland?

Cassia gum is known for its ability to absorb water and form a gel-like structure, making it an excellent thickener, stabilizer and emulsifier. In Finland, its incorporation into food formulations is rapidly growing, as manufacturers seek to replace synthetic chemicals with more natural alternatives.

The key reasons for the rising use of cassia gum powder in Finland are:

- Natural ingredient: As consumers continue to demand cleaner, plant-based food products, cassia gum powder provides a natural, functional alternative to artificial additives.

- Versatility: It can be used across a variety of food categories, including pet food and frozen meals, to improve texture, stability and shelf life.

- Non-toxic and biodegradable: Unlike some synthetic thickeners, cassia gum is a safe and environmentally friendly option for manufacturers and consumers alike.

How Does Cassia Gum Powder Benefit the Pet Food Sector in Finland?

In Finland, the pet food industry is increasingly focused on producing high-quality, nutritious and stable food products for pets. Cassia gum powder plays a significant role in this sector by improving product texture, consistency and shelf life. It is commonly incorporated into wet, semi-moist and canned pet food formulations.

Key benefits of cassia gum powder in pet food production:

- Texture and consistency: Cassia gum helps maintain a smooth, uniform texture in pet food, preventing separation during production and storage.

- Stabilization: It works synergistically with other stabilizers and emulsifiers, ensuring that the pet food maintains its desired consistency throughout its shelf life.

- Moisture retention: By retaining moisture in the product, cassia tora prevents drying out, keeping the pet food moist and palatable.

- Efficient processing: The inclusion of cassia gum streamlines the manufacturing process by reducing the need for more complex, synthetic additives, thus simplifying production and formulation.

With the growing demand for natural ingredients in pet food, cassia gum powder is emerging as an essential tool for pet food manufacturers in Finland who are looking to produce high-quality, clean-label products.

How Does Cassia Gum Powder Benefit the Frozen Foods Sector in Finland?

The frozen food sector in Finland is booming, driven by consumer demand for convenient, high-quality frozen meals, soups, sauces and ready-to-eat products. Cassia tora gum powder plays a crucial role in ensuring that these products maintain their texture and stability, both during freezing and after thawing.

Key applications of cassia gum powder in frozen foods:

- Texture retention: Cassia gum helps maintain the desired texture of frozen meals, preventing the products from becoming mushy or separating during the freezing and thawing process.

- Stabilizing sauces and soups: In frozen soups, sauces and ready-to-eat meals, cassia gum powder helps to maintain the desired viscosity and prevents separation, ensuring a smooth and consistent product.

- Moisture control: Cassia tora reduces moisture separation during both production and storage, which is particularly important in frozen foods that are prone to ice crystallization and freezer burn.

- Versatility in product types: Whether used in plant-based, meat-based or mixed frozen meals, cassia tora gum powder helps ensure the product remains stable, consistent and appealing to consumers.

As the demand for frozen foods continues to grow in Finland, cassia gum powder offers manufacturers a natural, reliable solution to improve the quality and stability of their frozen products.

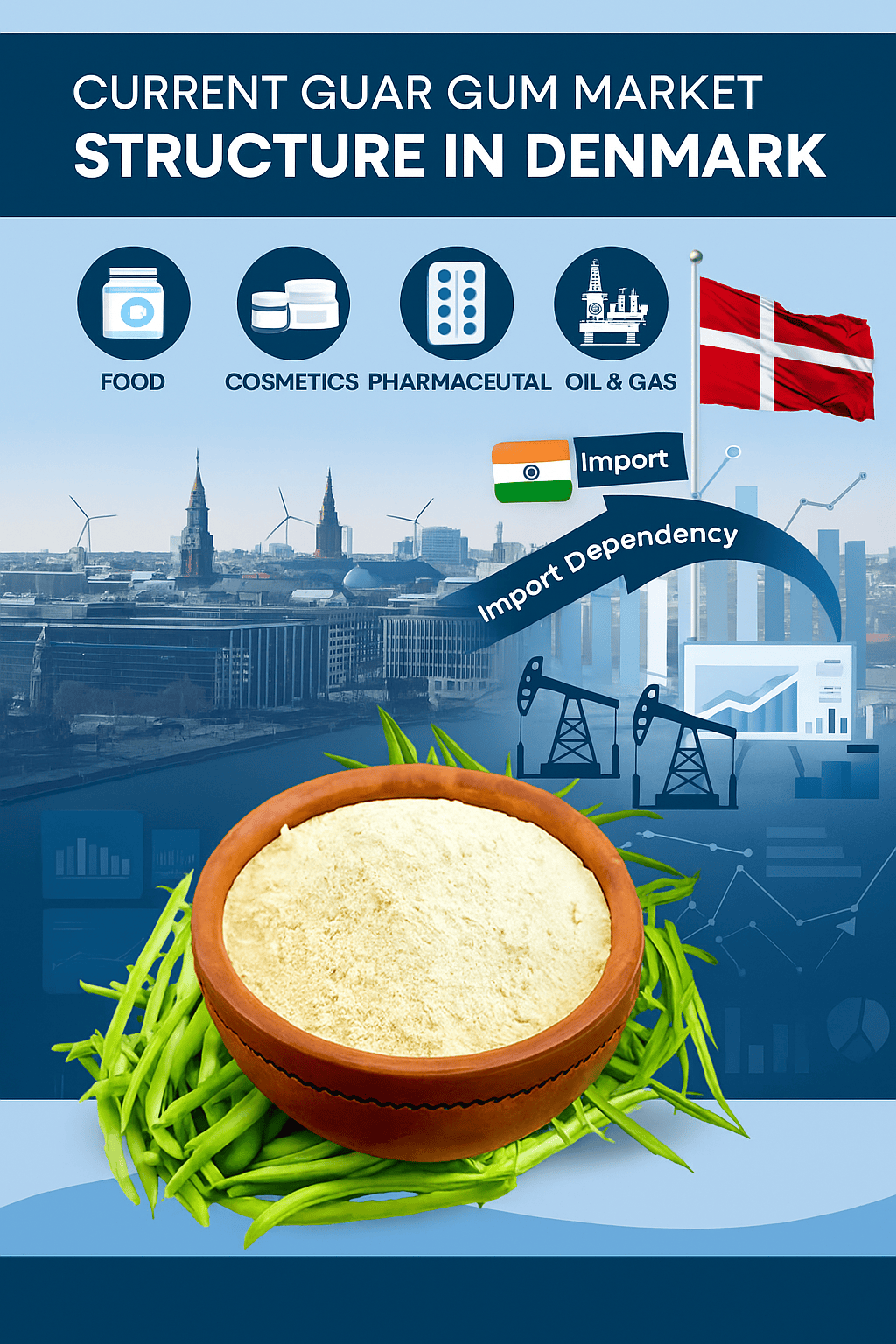

What Are the Market Dynamics of Cassia Gum Powder in Finland?

Several market dynamics are driving the adoption of Cassia Powder in Finland’s food industry, particularly in the pet food and frozen foods sectors.

Key dynamics include:

- Growing demand for processed pet food and frozen meals: As pet ownership increases and consumer preferences shift towards convenient meal options, there is a rising demand for high-quality, stable pet food and frozen meals in Finland.

- Import dependence: Cassia gum powder is primarily sourced from international suppliers, particularly from India. Finnish manufacturers rely on these imports to meet their demand for this critical ingredient, emphasizing the importance of strong international supply chains.

- Clean-label demand: Consumers in Finland are increasingly seeking food products with natural ingredients and fewer synthetic additives. The shift towards clean-label products has fueled the growth of Cassia Gum Powder, as it is a natural, plant-derived alternative to artificial emulsifiers and stabilizers.

- Health-conscious trends: As consumers become more health-conscious and demand products with natural, safe ingredients, manufacturers are turning to cassia gum to meet this trend in both pet food and frozen foods.

These dynamics are pushing cassia tora splits to the forefront of the Finnish food industry, as manufacturers strive to create high-quality powder, natural products that meet evolving consumer preferences.

What is the Impact of Cassia Gum Powder in Finland?

Cassia gum powder is primarily sourced from countries like India, where cassia tora is grown. While Finland does not produce cassia gum domestically, it has well-established import networks to ensure a consistent supply of this essential ingredient for the food and pet food sectors.

Key production and supply considerations:

- Handling and storage: Proper handling and storage are crucial to maintain the functional quality of cassia gum powder. It should be kept in a cool, dry place to preserve its gelling and thickening properties.

- Distribution networks: The Finnish distribution network for cassia powder is well-established, with a focus on meeting the needs of both the food and pet food industries. Suppliers ensure that manufacturers have reliable access to cassia powder for consistent production.

- Bulk supply availability: The availability of cassia powder in bulk is essential for large-scale food manufacturers. Efficient supply chains and import networks ensure that Finnish companies can receive the necessary quantities of cassia gum powder to maintain production schedules.

Conclusion

The increasing demand for natural, functional ingredients in Finland’s pet food and frozen food sectors is driving the growing adoption of cassia gum powder. With its ability to improve texture, stabilize emulsions and reduce moisture separation, cassia gum powder is proving to be an invaluable tool for manufacturers in Finland looking to meet consumer demand for clean-label, high-quality products. As the market for processed pet food and frozen meals continues to grow, cassia gum powder will undoubtedly play a significant role in shaping the future of Finland’s food production industry.

FAQs About Cassia Gum Powder

What is cassia gum powder and why is it used in pet food and frozen foods?

Cassia gum powder is a natural polysaccharide derived from the seeds of the cassia tora plant. It is used in pet food and frozen foods for its ability to improve texture, maintain consistency and stabilize products during production, freezing and storage.

How does cassia gum powder benefit the pet food industry in Finland?

In Finland’s pet food industry, cassia gum powder improves the texture and consistency of wet, semi-moist and canned pet food. It helps maintain product stability and moisture retention, ensuring the food remains fresh and appealing during storage.

What are the advantages of using cassia gum powder in frozen foods in Finland?

Cassia gum powder is used in frozen meals in Finland to retain texture after freezing and thawing. It also stabilizes sauces, soups and ready-to-eat frozen products, preventing moisture separation and improving the overall quality of the frozen food.

Is cassia gum powder safe for use in pet food and human food products?

Yes, cassia gum powder is safe for use in both pet food and human food products. It is a natural ingredient that is non-toxic and biodegradable, making it suitable for clean-label formulations.

CEO, Altrafine Gums

With over Four decades of expertise in the natural gums and hydrocolloids industry, Ajit Patel leads Altrafine Gums, a globally recognized manufacturer and exporter of Guar Gum Powder, Cassia Tora Powder (Cassia Gum Powder) and other Hydrocolloids. Under his visionary leadership, the company has built a strong reputation for quality, innovation, and reliability across the food, feed, pet feed, pharmaceutical, mining, oil drilling and cosmetic sectors.

Altrafine Gums has been serving global industries for decades with a focus on sustainable sourcing, research-driven production, and stringent quality control. Its wide product portfolio includes Guar Gum Powder, Cassia Tora Powder (Cassia Gum Powder) and other plant-based hydrocolloids that serve as key functional ingredients in diverse applications.

Ajit Patel’s commitment to excellence ensures that every product from Altrafine meets international standards of performance and purity. He is passionate about advancing the global reach of Indian hydrocolloids, fostering customer trust, and promoting eco-friendly, science-backed solutions that enhance product formulation and performance worldwide.