Guar Gum Powder for Premium Swiss Food Applications

Switzerland stands as a global beacon for culinary excellence and pharmaceutical-grade food safety. In a nation where “Swiss Made” is a synonym for perfection, the ingredients used in production must meet extraordinary benchmarks. Guar Gum Powder has emerged as a cornerstone ingredient within this landscape, serving as a vital hydrocolloid that ensures texture, shelf-life and consumer satisfaction. From the dairy processing plants in the Alps to the high-tech food labs in Zurich, High-Quality Guar Gum Powder is the silent architect of premium food structures.

1. Guar Gum Powder Demand In Switzerland’s Premium Food Manufacturing Hubs

In the metropolitan and industrial hearts of Zürich, Geneva and Lausanne, the demand for Guar Gum Powder is shaped by a shift toward “Clean Label” transparency. Consumers in these regions demand fewer synthetic additives, prompting premium food producers to turn to Guar Powder as a natural, plant-based alternative to modified starches and chemical stabilizers.

In Zürich, the hub of Swiss confectionery and dairy innovation, Guar Gum is prized for its ability to provide superior mouthfeel in low-fat applications. Whether it is a premium yogurt or a vegan dessert, manufacturers prioritize High-Quality Guar Gum Powder that offers immediate hydration and a smooth, non-gritty profile. Meanwhile, in Geneva and Lausanne, the focus is often on gluten-free bakery products. Here, Guar Powder acts as a structural substitute for gluten, providing the viscoelasticity required to trap air and ensure a soft, aerated crumb in artisanal breads. The influence of these hubs ensures that only the most refined grades of Guar Gum enter the Swiss supply chain.

2. Guar Gum Powder Role In High-Precision Processed Food Production

The industrial landscapes of Basel and Winterthur are home to some of the world’s most advanced food engineering facilities. In these “high-precision” environments, High Performance Guar Gum is essential because of its predictable rheological properties. Manufacturers here operate under strict “just-in-time” and automated processing conditions where ingredient variability can lead to costly downtime.

In Basel, particularly within the intersection of food science and nutrition, Guar Gum Powder is utilized for its high viscosity at low concentrations. This efficiency allows for “High-Precision” stabilization in liquid sauces and dressings, ensuring that emulsions do not separate even under the stress of high-shear mixing or temperature fluctuations. Winterthur’s processed food sector relies on the cold-water solubility of Guar Powder, which allows for energy-efficient production cycles. By using a High Performance Guar Gum, these manufacturers ensure that every batch of soup or sauce produced maintains a mathematically precise thickness, reflecting the Swiss commitment to technical accuracy.

3. Guar Gum Powder Quality-First Sourcing Criteria Used By Swiss Buyers

Procurement teams in the administrative and financial centers of Bern and Zug approach the purchase of Guar Gum Powder with a “Quality-First” mindset. For these buyers, price is often secondary to the reliability of specifications and the integrity of the supply chain.

The sourcing criteria in Bern are heavily influenced by Swiss federal food safety regulations. Buyers demand High-Quality Guar Gum Powder that comes with comprehensive COA (Certificate of Analysis) reports, detailing microbiological purity, heavy metal limits and mesh size consistency. In Zug, a global hub for commodity trading and logistics, the emphasis is on traceability. Swiss buyers require a transparent “farm-to-fork” trail, ensuring that the Guar Powder is ethically sourced and free from cross-contamination. This rigorous vetting process ensures that only suppliers who can guarantee long-term supply continuity and adherence to ISO and FSSC 22000 standards are selected.

Our Other Product

Cassia Tora Powder4. Guar Gum Powder Supplier Qualification and Sampling Approach In Switzerland

The path to becoming a certified supplier for food producers in Zürich, St. Gallen and Geneva is paved with intensive scrutiny. The qualification process for Guar Gum Powder typically begins with a multi-stage sampling protocol.

Initially, manufacturers in St. Gallen perform “bench-top” testing to evaluate how a specific batch of Guar Powder interacts with local water hardness and other ingredients. This is followed by “Pilot Plant” trials in Zürich, where the high performance guar gum is subjected to actual processing conditions, such as UHT (Ultra-High Temperature) treatment or rapid freezing. In Geneva, documentation checks are equally rigorous; suppliers must provide detailed data on the galactomannan content and hydration rates. Consistency is the ultimate goal – Swiss buyers are not just looking for a good sample; they are looking for a supplier whose tenth batch is identical to their first.

5. Guar Gum Powder Handling and Storage Practices To Preserve Performance

Maintaining the functional integrity of Guar Gum Powder requires world-class logistics, which is a specialty of facilities in Lugano, Bern and Zürich. Because Guar Powder is highly hygroscopic (moisture-absorbing), improper storage can lead to lumping and a significant loss in viscosity potential. In the southern hub of Lugano, where humidity can vary, climate-controlled warehousing is the standard.

Facilities utilize advanced HVAC systems to maintain a constant, low-moisture environment to prevent the High-Quality Guar Gum Powder from degrading. In Bern and Zürich, “First-In, First-Out” (FIFO) inventory management is strictly enforced through automated warehouse management systems. By keeping the powder in its original, multi-wall paper bags with moisture barriers and stored on pallets away from walls, Swiss manufacturers ensure that the high performance guar gum retains its full thickening power until the moment it enters the production line.

Read Our Article

Top Benefits of Using Guar Gum Powder in Ketchup Production6. Guar Gum Powder Long-Term Sourcing Strategy For Stable Supply And Brand Trust

For premium brands in Lausanne, Zürich and Basel, sourcing Guar Gum Powder is not a transactional interaction; it is a strategic partnership. These manufacturers recognize that any disruption in the supply or quality of Guar Powder could jeopardize their brand’s reputation for consistency. Long-term strategies in Lausanne often involve multi-year contracts that include “buffer stock” agreements, where the supplier maintains a reserved inventory of High-Quality Guar Gum Powder specifically for the Swiss client. In Basel, sourcing strategies are increasingly focused on sustainability and ESG (Environmental, Social and Governance) goals. By partnering with suppliers who invest in sustainable farming practices for guar beans, Swiss manufacturers build brand trust with an eco-conscious public. This collaborative approach minimizes risk, ensures price stability in a volatile market and guarantees that the high performance guar gum remains a reliable component of Switzerland’s premium food exports.

FAQs About Guar Gum Powder

Why do Swiss manufacturers prefer Guar Powder over other stabilizers?

Swiss producers value Guar Powder for its natural, clean-label profile and its high-efficiency cold-water solubility, which aligns with premium "Swiss Made" quality standards.

How is the quality of Guar Gum Powder verified in Zürich and Geneva?

Quality is verified through rigorous multi-batch sampling, viscosity titration tests and comprehensive documentation checks to ensure full traceability and microbiological safety.

Does Guar Gum Powder affect the taste of Swiss chocolate or dairy?

High-Quality Guar Gum Powder is neutral in taste and odor, ensuring that it enhances texture and stability without altering the delicate flavor profiles of premium Swiss products.

What storage conditions are necessary for High Performance Guar Gum?

It must be stored in cool, dry and climate-controlled environments in Lugano and Bern to prevent moisture absorption and maintain its functional thickening properties.

How do Swiss buyers mitigate supply chain risks for Guar Powder?

They utilize long-term sourcing partnerships, maintain strategic buffer stocks in centers like Zug and prioritize suppliers with transparent, sustainable "farm-to-fork" traceability.

CEO, Altrafine Gums

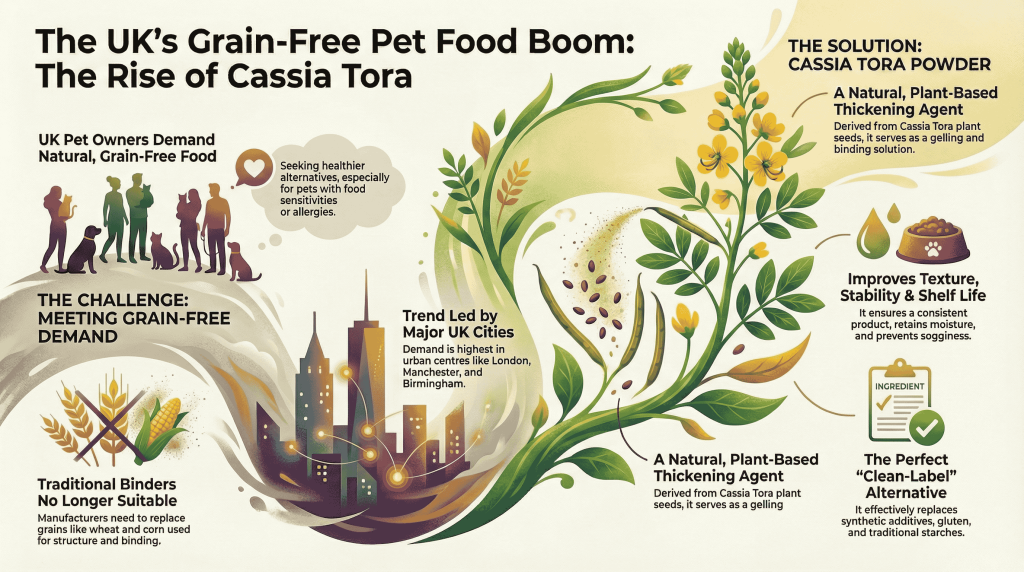

With over Four decades of expertise in the natural gums and hydrocolloids industry, Ajit Patel leads Altrafine Gums, a globally recognized manufacturer and exporter of Guar Gum Powder, Cassia Tora Powder (Cassia Gum Powder) and other Hydrocolloids. Under his visionary leadership, the company has built a strong reputation for quality, innovation, and reliability across the food, feed, pet feed, pharmaceutical, mining, oil drilling and cosmetic sectors.

Altrafine Gums has been serving global industries for decades with a focus on sustainable sourcing, research-driven production, and stringent quality control. Its wide product portfolio includes Guar Gum Powder, Cassia Tora Powder (Cassia Gum Powder) and other plant-based hydrocolloids that serve as key functional ingredients in diverse applications.

Ajit Patel’s commitment to excellence ensures that every product from Altrafine meets international standards of performance and purity. He is passionate about advancing the global reach of Indian hydrocolloids, fostering customer trust, and promoting eco-friendly, science-backed solutions that enhance product formulation and performance worldwide.