Advances in Food Biochemistry Put Cassia Gum in the Front Line

The cassia gum is purified flour from the seed endosperm of cassia tora and the cassia obtusifolia, which are plants of the leguminosae family. 75% of the powder chemically contains high molecular weight polysaccharides with mannopyrannose units linked with galactopyrannose units. These make it exhibit excellent properties of a hydrocolloid.

The manufacturing process is a series of steps involving the cleaning of the source material, removal of impurities, milling and further refining with isopropanol to have a final purified product.

Characterization of the Cassia Gum

The final refined cassia gum is significantly different from the other galactomanans in that it has fewer galactose molecules next to the long mannose chain. This creates a significant effect on the synergy of the food grade cassia gum with other anionic food gums such as carrageenan or Xanthan gums.

Scientific research has shown that a high number of galactose side chains hinder proper synergistic gelling effects with anionic polymers. To counter this effect, a smaller amount of hydrocolloid blend with cassia gum is required for a similar effect to be achieved in the food product as with carrageenan alone or blends of carrageenan and other hydrocolloids.

Reaction of the Cassia Gum in Foods

In regards to the chemical structure of the gum, it is stable during food processing and storage. The product only degrades into sugars, but this happens rarely. Scientific research on degradation of the cassia gum in food products shows that it is stable without chemical modifications for over 20 months. When the gum is used at the recommended levels in food, it has been seen to have no interaction with nutrients. There is no other seen by products of the degradation process of the gum apart from sugar formation.

Usage Levels of Cassia Gum in Foods

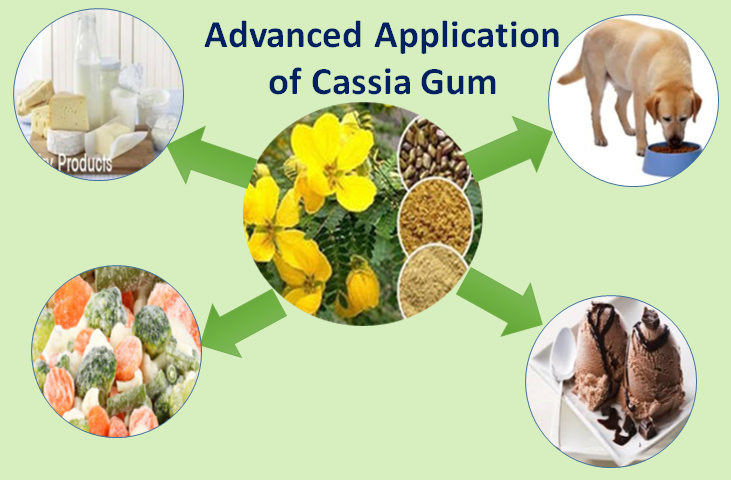

In cheeses, such as curd, whey, cream, processed spread, dip and other miscellaneous cheeses, it is used at a maximum level of 3 mg/kg as an emulsifier, stabilizer, thickening agent and water retention agent in these formulations.

In the frozen dairy desserts and mixes, the gum powder is used at a level of 2.5 mg/kg as an emulsifier and stabilizer to control over run. These products include ice creams, ice milks and sherbets.

In the meat products and meat formulations and dishes, it is used at a level of 3.5 mg/kg as a stabilizer, emulsifier and water retaining agent. These include multi coarse meat meals, sandwich ingredients and commercially processed meat ingredients.

In poultry products it is also used at a level of 3.5mg/kg as a stabilizer and water retaining agent. These include all poultry containing dishes frozen products and sandwiches.

Bottom Line

Continued research on the cassia gum powder uses and applications has led to the conclusion that the gum can be equally used as replacement to other hydrocolloids and in some cases it is more effective. Research has also proven that the gum is effective when combined with other hydrocolloids such as the carrageenan and the xanthan gum. In addition to human food additives, it can also be used in the manufacturing of pet foods.

CEO, Altrafine Gums

With over Four decades of expertise in the natural gums and hydrocolloids industry, Ajit Patel leads Altrafine Gums, a globally recognized manufacturer and exporter of Guar Gum Powder, Cassia Tora Powder (Cassia Gum Powder) and other Hydrocolloids. Under his visionary leadership, the company has built a strong reputation for quality, innovation, and reliability across the food, feed, pet feed, pharmaceutical, mining, oil drilling and cosmetic sectors.

Altrafine Gums has been serving global industries for decades with a focus on sustainable sourcing, research-driven production, and stringent quality control. Its wide product portfolio includes Guar Gum Powder, Cassia Tora Powder (Cassia Gum Powder) and other plant-based hydrocolloids that serve as key functional ingredients in diverse applications.

Ajit Patel’s commitment to excellence ensures that every product from Altrafine meets international standards of performance and purity. He is passionate about advancing the global reach of Indian hydrocolloids, fostering customer trust, and promoting eco-friendly, science-backed solutions that enhance product formulation and performance worldwide.