Properties of Sesbania Gum Powder that makes it useful for Textile Industry

What is Sesbania Gum Powder?

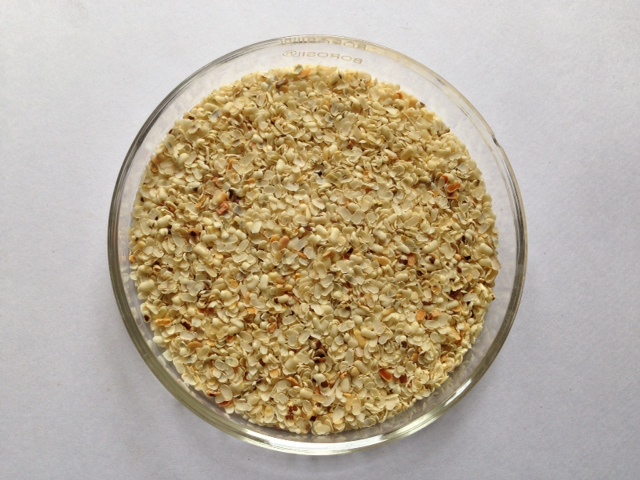

Sesbania gum powder is undoubtedly one of the most commonly used additive substance in the manufacturing industry more so the textile industry. Sesbania gum as well as sesbania gum powder is derived from the seeds of the sesbania plant which commonly grows in the regions of Asia, China as well as parts of Africa. The sesbania plant is a short annual plant that grows to a height of two metres and produces the sesbania seeds referred to as sesbania aculeate. The tough, short stemmed, fibrous, yellow flowered and purple spotted shrubs produce light brown sesbania seeds which are the main ingredients for Sesbania gum or goma sesbania in Spanish.

Sesbania gum powder is undoubtedly one of the most commonly used additive substance in the manufacturing industry more so the textile industry. Sesbania gum as well as sesbania gum powder is derived from the seeds of the sesbania plant which commonly grows in the regions of Asia, China as well as parts of Africa. The sesbania plant is a short annual plant that grows to a height of two metres and produces the sesbania seeds referred to as sesbania aculeate. The tough, short stemmed, fibrous, yellow flowered and purple spotted shrubs produce light brown sesbania seeds which are the main ingredients for Sesbania gum or goma sesbania in Spanish.

The process of making goma sesbania or gum powder from sesbania seeds involves harvesting the pods, sorting the sesbania seeds, roasting the kernels to separate the husks and the seeds, splitting the seeds to retrieve the endosperm from the germ ,milling and finally screening to come up with a creamy powder which when dissolved in water becomes a gum.

Properties of Sesbania Gum Powder That Make It Ideal for Textile Industry

• Goma sesbania or gum derived from sesbania beans is a pale white creamy powder that features the following properties:

• The additive is highly soluble in both cold as well as hot water hence making a suitable viscosity agent.

• Gum from sesbania beans has wide temperature variations which make it flexible to use in different textile processes.

• The textile additive is insoluble in many inorganic solvents such as alcohol, ethers, ketones and other organic solvents consequently making the gum powder salt and brine resistant.

• Sesbania gum powder for textiles has a high viscosity which is 5 to 10 times stronger than most commonly used gum or gelling compounds. This is attributed to its high pH range of between 6 and 11.

• The gum from sesbania seeds has good stabilizing properties due to it being a galactomannan polysaccharide with a minimum viscosity of 2000-2500cps and a maximum of 3000-3500cps.

• Gum from the sesbania seeds has good gelling properties credited to a low moisture content of 12% as well as its pseudoplastic film forming properties.

Applications of Sesbania Gum Powder in Textile Industry

Sesbania gum powder for textiles is used in various processes in the industrial sector with the following being most notable:

• Sesbania gum powder is used as a sizing agent with the aim of making the fabric stronger, smoother and adheres to dyes without the colors running.

• The salt and brine resistant properties of sesbania gum make the process of bleaching and refining the final fabric easier and convenient since the solutions will not harm the textile material.

• Gum from the sesbania seeds is used as a dye thickener in the textile industry thus allowing the dyes or stains to adhere better to the fabric without running or blotting.

Conclusion

Latest statistics show a growing trend in regard to the use of sesbania gum powder for textiles; this is pegged on the technological revolution that is leading to growth in textile industries both locally, regionally as well as globally. In order to ensure that the current as well as future demands are met, it is highly advisable to empower the cultivation of sesbania plant to boost production.

This Article has been written & posted by Ajit Patel.