Fast Hydration Slurriable Guar in Deep Hole Drilling: Managing Waste Removal and Fluid Stability

Table of Contents

In the dynamic world of deep hole drilling, managing waste removal and maintaining fluid stability are two critical components of ensuring efficient operations. To achieve these goals, the use of high-quality additives like Fast Hydration Slurriable Guar Gum has become indispensable. This innovative material plays a pivotal role in improving drilling performance, facilitating waste removal and stabilizing drilling fluids. In this article, we will explore the various aspects of using fast hydration guar gum products in deep hole drilling, focusing on their role in enhancing fluid stability and optimizing waste management processes.

How High-Viscosity Guar Gum Enhances Drilling Mud Consistency

In deep hole drilling, maintaining the right viscosity of drilling mud is crucial for several reasons, including effective cuttings removal and overall drilling efficiency. One of the key additives in drilling fluids is guar gum, specifically the high-viscosity variety, which is known for its ability to thicken the mud, making it more effective in these processes.

Fast Hydration Guar Gum plays an essential role in enhancing the viscosity of drilling mud. Its ability to rapidly hydrate upon mixing ensures that the drilling fluid maintains the required consistency, even in challenging drilling conditions. This ensures that the drilling fluid performs optimally, facilitating the efficient transportation of cuttings to the surface and providing necessary lubrication to the drill bit, which helps prevent overheating and wear.

The high viscosity also aids in preventing the unwanted settling of solids within the drilling fluid. This keeps the fluid in a stable, homogeneous state, which is essential for ensuring that the mud flows evenly through the system and maintains its effectiveness over extended drilling periods. In this way, Fast-Hydration Guar Gum Powder supports not only the physical properties of the fluid but also contributes to operational efficiency, reducing downtime and maintenance needs during drilling operations.

Read Our Article: How Guar Gum Powder Reduces Water Loss in Broken Geological Formations

The Science Behind Guar as a Suspended Agent in Drilling Fluids

Guar gum is well-regarded for its ability to act as a suspended agent in drilling fluids, a function that is particularly important when drilling through deep or challenging geological formations. By adding fast hydration guar gum to the drilling fluid, operators can effectively suspend solid materials, such as drill cuttings and ensure their efficient removal from the borehole.

The rapid hydration slurriable guar gum works by quickly absorbing water and swelling to form a gel-like consistency. This enables the fluid to maintain a suspension of solid particles, preventing the cuttings from settling at the bottom of the wellbore. In deep hole drilling, the volume of solids generated is significant and the ability to suspend these materials is crucial to maintaining a clean and functional drilling environment.

In challenging environments where drill cuttings can accumulate quickly and potentially cause blockages or inefficiencies, the use of rapid hydration guar gum becomes even more valuable. Its ability to prevent the buildup of solids helps reduce the risk of equipment damage and wellbore instability, thereby improving the overall safety and reliability of drilling operations.

Our Other Product: Cassia Tora Powder

Fast Hydration Slurriable Guar’s Impact on Waste Removal in Deep Hole Drilling Operations

One of the most significant challenges in deep hole drilling is the efficient removal of waste materials, such as drill cuttings and other solids. These materials, if not properly managed, can impede the drilling process and lead to operational inefficiencies. Fast Hydration Slurriable Guar plays a critical role in addressing this challenge by significantly improving waste removal.

The high hydration rate of fast hydration guar gum ensures that the drilling fluid maintains its thickening properties, even in demanding conditions. This helps to move the drill cuttings efficiently from the drill site to the surface, minimizing the risk of clogs or blockages that can slow down the operation. Furthermore, because the guar gum forms a stable gel, it prevents the solids from settling in the fluid system, ensuring that they remain suspended and are continuously circulated to the surface. By optimizing the waste removal process, fast hydration guar gum helps to reduce downtime associated with cleaning and maintaining drilling equipment. This translates into more cost-effective operations and increased drilling productivity, which is essential in a competitive drilling environment.

Read Our Article: How Fast Hydrating Guar Gum Enhances the Performance of Diesel Fuel Additives?

Optimizing Fluid Stability with Fast Hydrating Guar Gum for Deep Drilling Efficiency

Fluid stability is paramount in deep hole drilling, as unstable fluids can lead to various issues, including wellbore collapse and difficulties in maintaining drill bit efficiency. To prevent such problems, drilling operators rely on the stabilizing properties of guar gum, specifically fast hydration slurriable guar, to maintain the integrity of the fluid throughout the drilling process.

The Fast Hydration Guar Gum functions as a stabilizing agent by providing the necessary thickness and viscosity to the drilling fluid, which helps to prevent fluid loss into the surrounding formation. This stabilization is especially important when drilling in porous or fractured formations, where excessive fluid loss can compromise the efficiency of the drilling operation. Additionally, the rapid hydration characteristics of fast hydration guar gum allow for a quicker setup of the drilling fluid, ensuring that the fluid remains stable even under varying pressure and temperature conditions. The ability to quickly adapt to these changes ensures that drilling performance remains consistent and that wellbore stability is preserved, reducing the risk of complications such as wellbore collapse or stuck pipe incidents.

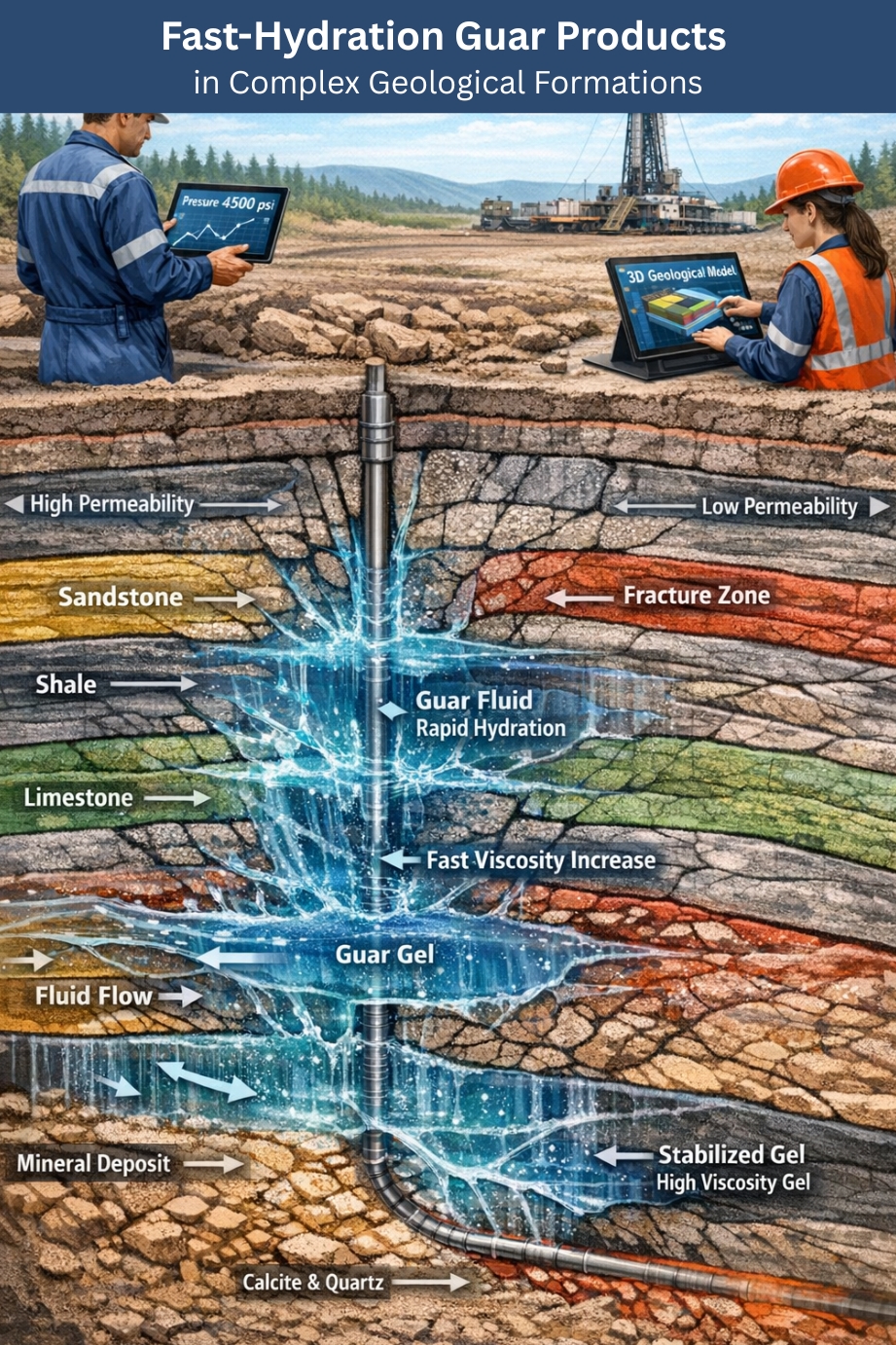

The Role of Fast-Hydration Guar Products in Complex Geological Formations

Drilling in complex geological formations, such as those with varying pressures, temperatures and rock types, presents significant challenges. In such conditions, drilling fluids must be adaptable, providing the necessary properties to handle changes in the environment. Fast-hydration guar products are particularly well-suited for this purpose, offering enhanced flexibility and performance in these variable conditions.

In formations with high-pressure zones, rapid hydration slurriable guar gum ensures that the drilling fluid can adjust quickly to changes in the wellbore conditions. This quick response helps to maintain the fluid’s ability to suspend solids and maintain appropriate viscosity, regardless of the surrounding geological environment. This adaptability is crucial for minimizing the risk of wellbore instability or damage, which can significantly delay drilling operations and increase costs.

Additionally, in formations with challenging rock types, where traditional drilling fluids might struggle to maintain stability, fast hydration guar gum contributes to improved fluid cohesion and reduces the likelihood of excessive fluid loss or premature breakdown of the fluid’s properties. This results in more consistent drilling performance, even in complex and difficult geological formations.

Key Benefits of Guar Gum in Minimizing Fluid Loss and Maximizing Drilling Efficiency

Fluid loss is a common issue in deep hole drilling operations, particularly in permeable formations where drilling fluids can seep into the surrounding rock. This not only reduces the effectiveness of the drilling fluid but also increases the costs associated with fluid replenishment. By incorporating Fast Hydration Guar into the drilling fluid, operators can minimize fluid loss and enhance the overall efficiency of their drilling operations.

The thickening properties of fast hydration guar gum powder help form a barrier within the formation, preventing excessive fluid loss. This barrier ensures that the drilling fluid remains effective in transporting cuttings, cooling the drill bit and providing the necessary lubrication throughout the drilling process. By reducing fluid loss, operators can maintain a consistent level of drilling fluid, preventing interruptions and delays caused by fluid replenishment.

In addition to minimizing fluid loss, fast hydration guar gum enhances the overall drilling efficiency by providing stable fluid characteristics over long periods of operation. This stability ensures that the fluid performs optimally, reducing the need for frequent adjustments and maintenance during drilling. As a result, drilling operations become more efficient, cost-effective and less prone to downtime.

Our Other Product: Guar Gum Powder

Altrafine Gums: Pioneering Innovation in Guar Gum Products

At Altrafine Gums, we take pride in producing high-quality guar gum products that are essential for optimizing deep hole drilling operations. As one of the largest manufacturers and processors of guar gum powder, cassia tora powder and fast hydration slurriable guar, our commitment to excellence is reflected in every product we offer.

With state-of-the-art infrastructure and rigorous quality control measures, we ensure that our products meet the highest standards in the industry. Our rapid hydration guar gum products are designed to enhance fluid stability, optimize waste removal and improve overall drilling efficiency, making them the preferred choice for drilling companies around the world. We understand the challenges that come with deep hole drilling and are dedicated to providing products that not only meet the technical requirements of our clients but also contribute to the overall success of their operations. By continuously innovating and expanding our product range, we aim to offer cutting-edge solutions that address the evolving needs of the drilling industry.

Fast Hydration Slurriable Guar Gum for Deep Hole Drilling: Fluid Stability & Waste Removal

In the demanding field of deep hole drilling, the use of fast hydration slurriable guar gum is an indispensable tool for optimizing fluid stability and managing waste removal. By enhancing the viscosity of drilling mud, suspending drill cuttings and stabilizing the drilling fluid, guar gum plays a crucial role in ensuring smooth, efficient drilling operations. As the drilling industry continues to evolve, the role of fast hydration guar gum in addressing the challenges of waste removal and fluid stability will only become more important, driving further advancements in drilling technology.

FAQs About Fast Hydration Slurriable Guar

What is Fast Hydration Guar Gum used for in deep hole drilling?

Fast Hydration Guar Gum is used to enhance the viscosity of drilling mud, ensuring optimal waste removal and fluid stability during deep hole drilling operations.

How does Fast Hydration Guar improve waste removal in drilling?

Fast Hydration Guar Gum helps suspend drill cuttings and solids, preventing clogs and ensuring efficient removal to maintain smooth drilling operations.

Can Fast Hydration Guar Gum be used in challenging geological formations?

Yes, Fast Hydration Guar Gum adapts well to varying geological conditions, providing consistent fluid stability and reducing fluid loss in complex environments.

Why is fluid stability important in deep hole drilling?

Fluid stability prevents wellbore instability, reduces equipment wear, and ensures smooth operation by maintaining consistent viscosity and preventing fluid loss.

How does Fast Hydration Guar enhance drilling efficiency?

By maintaining stable, high-viscosity fluids, Fast Hydration Guar Gum ensures effective lubrication, cuttings transport, and overall drilling efficiency.

CEO, Altrafine Gums

With over Four decades of expertise in the natural gums and hydrocolloids industry, Ajit Patel leads Altrafine Gums, a globally recognized manufacturer and exporter of Guar Gum Powder, Cassia Tora Powder (Cassia Gum Powder) and other Hydrocolloids. Under his visionary leadership, the company has built a strong reputation for quality, innovation, and reliability across the food, feed, pet feed, pharmaceutical, mining, oil drilling and cosmetic sectors.

Altrafine Gums has been serving global industries for decades with a focus on sustainable sourcing, research-driven production, and stringent quality control. Its wide product portfolio includes Guar Gum Powder, Cassia Tora Powder (Cassia Gum Powder) and other plant-based hydrocolloids that serve as key functional ingredients in diverse applications.

Ajit Patel’s commitment to excellence ensures that every product from Altrafine meets international standards of performance and purity. He is passionate about advancing the global reach of Indian hydrocolloids, fostering customer trust, and promoting eco-friendly, science-backed solutions that enhance product formulation and performance worldwide.